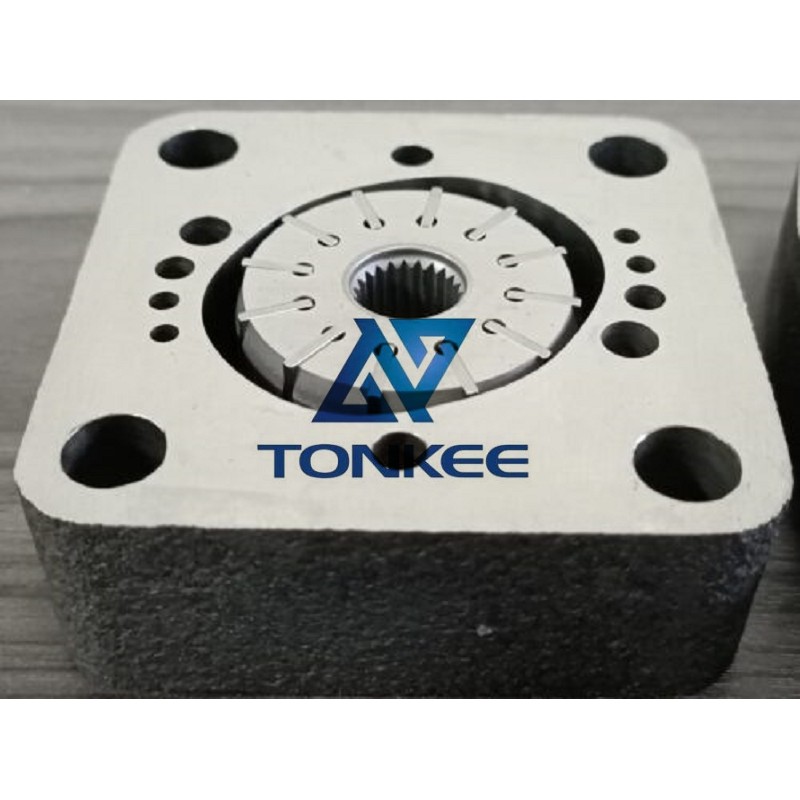

Vane cartridges for Vickers V10 pumps are manufactured using high-quality materials that ensure durability and longevity.

These cartridges are typically made from hardened steel or other robust materials that can withstand high pressures and continuous operation. The use of such materials ensures that the vane cartridges can effectively handle the rigors of hydraulic systems and provide reliable performance over an extended period.

One of the key specifications of vane cartridges is their dimensional accuracy. These cartridges are precisely machined to meet strict tolerances, allowing them to fit seamlessly into the pump housing. The precise dimensions ensure proper alignment and engagement of the vanes with the pump's rotor, resulting in efficient fluid displacement and minimal leakage.

The vane cartridges feature multiple vanes that are evenly spaced around the rotor. These vanes slide in and out of slots in the rotor as it rotates, creating chambers of varying sizes that draw in and expel hydraulic fluid. The design of the vane cartridges maximizes volumetric efficiency and minimizes internal leakage, contributing to the overall efficiency of the Vickers V10 pump.

Another important specification of vane cartridges is their surface finish.

The surfaces of the vanes and the rotor are carefully ground and polished to reduce friction and wear. The smooth surfaces allow for smooth operation and reduce energy losses within the pump. Additionally, the surface finish plays a vital role in preventing the buildup of contaminants, such as debris or particles, which could lead to premature wear or damage.

Vane cartridges for Vickers V10 pumps also incorporate advanced sealing mechanisms. The cartridges are equipped with high-quality seals that prevent fluid leakage and maintain optimal pressure levels within the pump. These seals are designed to withstand the demanding conditions of hydraulic systems, including high pressures and temperature differentials, ensuring reliable performance under various operating conditions.